The Top Benefits of Using Plastic Instead of Metal for Injection Molding

The global marketplace is competitive and continually changing. Companies working to stay at the forefront of their industry need to be flexible and able to react quickly to changes. They always need to be improving efficiency and quality without seeing a corresponding rise in costs. The conflict between quality and expense is a principal reason plastic has become an increasingly compelling material for the injection molding process.

The global marketplace is competitive and continually changing. Companies working to stay at the forefront of their industry need to be flexible and able to react quickly to changes. They always need to be improving efficiency and quality without seeing a corresponding rise in costs. The conflict between quality and expense is a principal reason plastic has become an increasingly compelling material for the injection molding process.

Plastic Reduces Costs

A distinct advantage, the one most people recognize, of plastic injection molding is the reduced cost of raw materials. Plastics are cheaper to work with than metals, while still exhibiting many of the same characteristics. Plastic polymers can also have a wide range of properties that were historically metal characteristics like thermal conduction and chemical resistance

The cost-savings from plastics cascade throughout the whole process. Plastic materials are usually lighter than their metal counterparts. The reduced weight can be helpful for the end product, but the impact of reduced weight affects the whole manufacturing process. Reduced weight makes shipping and packaging cheaper than metal parts. It can make installation and use simpler for customers.

Plastic Injection Molding is Smaller & Faster

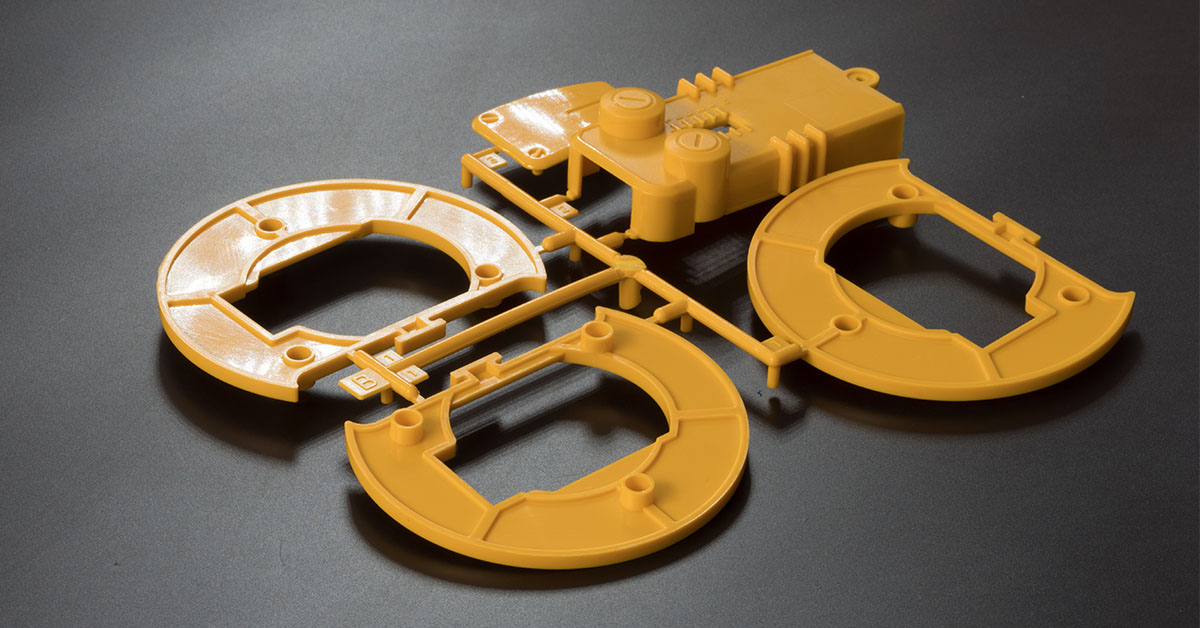

Not only are the raw materials cheaper, but the number of components per piece can be smaller as well. Some metal pieces are the result of several parts assembled into one final piece. Plastic molding can sometimes construct that same section as one whole piece with no independently produced segments. This can mean building fewer components with a less costly material than metal.

Plastics are not only lighter but are also faster to work with. Plastic molding can have a quicker cycle time than metal molding. A speedier cycle time means you can get to market faster. It also suggests that adjustments are easier to make. If the demands of the marketplace change then product pivoting can be faster with plastic.

More Applications are Using Plastic Injection Molding

Plastic molding is not the answer to all molding projects. There are compelling reasons to use metal as a raw material. In some cases, plastics cannot provide the characteristics needed for a particular product. However, the number of projects where this is true is not as significant as common knowledge suggests and that gap is shrinking with every year.

Developments in recent years, coupled with upcoming developments in plastics injection, make plastic a real contender for a vast range of molding possibilities. Reduced weight, reduced cost, single component molds, and the increasing capabilities of polymers means plastic injection molding can improve many existing processes. Considering plastic injection molding over metal injection molding for future and current products can mean significant cost savings.

Universal Plastic Mold has spent fifty years helping its customers utilize plastics in their injection molding processes. UPM assists companies in recognizing the benefits of plastics to their methods by providing custom plastic injection molding and related services, from development to assembly. Learn more about how UPM can help you at by contacting us today.